MDO plywood is a versatile and durable material widely used in construction and signage. But what makes it different from regular plywood? Let’s dive in.

MDO plywood, or Medium-Density Overlay plywood, is a specially engineered type of plywood designed for durability and weather resistance. It features a smooth, resin-impregnated fiber surface, which enhances its strength and makes it highly suitable for outdoor use. This overlay not only provides an excellent finish but also helps protect the plywood from moisture, making it an ideal choice for applications exposed to the elements, such as signage, exterior walls, and outdoor furniture. Additionally, MDO plywood offers superior resistance to wear and tear, ensuring it maintains its structural integrity even under challenging conditions. Whether for construction, painting, or long-term exposure, MDO plywood delivers reliability and performance..

MDO plywood has gained popularity in a variety of industries, from construction to signage. Whether you’re building a home or a billboard, understanding MDO plywood’s unique properties can help you make the right choice for your project. Read on to learn more about its benefits, uses, and how it compares to other types of plywood.

✔

MDO plywood is specially designed for exposure to weather, making it an excellent choice for outdoor construction and signage, providing added durability.

✖

MDO plywood has a special overlay that makes it more durable and resistant to moisture compared to standard plywood, offering better performance in outdoor environments.

What Is MDO Plywood?

MDO (Medium Density Overlay) plywood is a high-performance material designed to withstand outdoor conditions. It consists of a veneer core (typically made from softwood) with a smooth, resin-impregnated fiber overlay on one or both sides. This overlay gives the plywood a dense, smooth surface that is resistant to moisture, chemicals, and abrasion.

The unique properties of MDO plywood make it ideal for applications where strength, durability, and resistance to the elements are required. Its surface is smooth enough to accept paint or other coatings, which is why it’s commonly used in signage, outdoor furniture, and construction.

While MDO plywood is often compared to regular plywood, the primary difference is the added overlay that enhances its durability and performance in harsh conditions. The medium-density fiberboard overlay improves the bonding strength between the wood layers and provides a superior surface finish.

How Is MDO Plywood Made?

MDO plywood is manufactured using the same process as regular plywood, but with an additional step. The core consists of layers of wood veneer, typically made from hardwood or softwood, bonded together with waterproof glue. Once the basic plywood is created, a resin-impregnated fiber overlay is applied to one or both sides of the plywood, which is then heat-pressed to cure the resin.

This overlay is what distinguishes MDO plywood from regular plywood. The resin makes the surface smooth, durable, and resistant to water, chemicals, and physical damage. This unique manufacturing process results in a plywood product that can be used in a variety of demanding applications.

The resin-impregnated layer provides enhanced performance, making it more resistant to wear and tear compared to other types of plywood, especially in outdoor or commercial environments.

Common Uses of MDO Plywood

MDO plywood is used in a variety of industries, especially in applications where its strength and resistance to the elements are required. Here are some common uses:

1. Signage

MDO plywood is commonly used for making outdoor signs because of its smooth surface, which is perfect for painting. It is often used in both temporary and permanent signage for businesses, traffic signs, and billboards.

2. Construction

MDO plywood is widely used in the construction of buildings, particularly for applications like exterior sheathing, roofing, and soffits. Its moisture resistance makes it ideal for areas exposed to the elements.

3. Furniture

Outdoor furniture manufacturers often use MDO plywood for its durability and ability to withstand weathering. It’s especially used for patio tables, benches, and storage cabinets.

4. Marine Applications

Due to its resistance to water and chemicals, MDO plywood is sometimes used in marine applications like boat building and other water-exposed constructions.

Benefits of MDO Plywood

MDO plywood has several advantages that make it a popular choice for both professionals and DIY enthusiasts. Here are some of its key benefits:

1. Durability

The resin overlay makes MDO plywood highly resistant to moisture, weather, and physical damage. This durability ensures that it lasts longer in outdoor conditions compared to regular plywood.

2. Smooth Surface for Painting

The smooth surface of MDO plywood is perfect for painting or applying coatings, making it ideal for signage and decorative outdoor projects. The surface can accept multiple coats of paint, ensuring the final product is vibrant and long-lasting.

3. Moisture Resistance

MDO plywood’s resistance to water makes it suitable for outdoor applications, including use in environments with high humidity or direct exposure to rain.

4. Strength and Stability

The veneer core gives MDO plywood strength and stability, preventing it from warping or twisting even in challenging weather conditions. This makes it a reliable material for both indoor and outdoor construction.

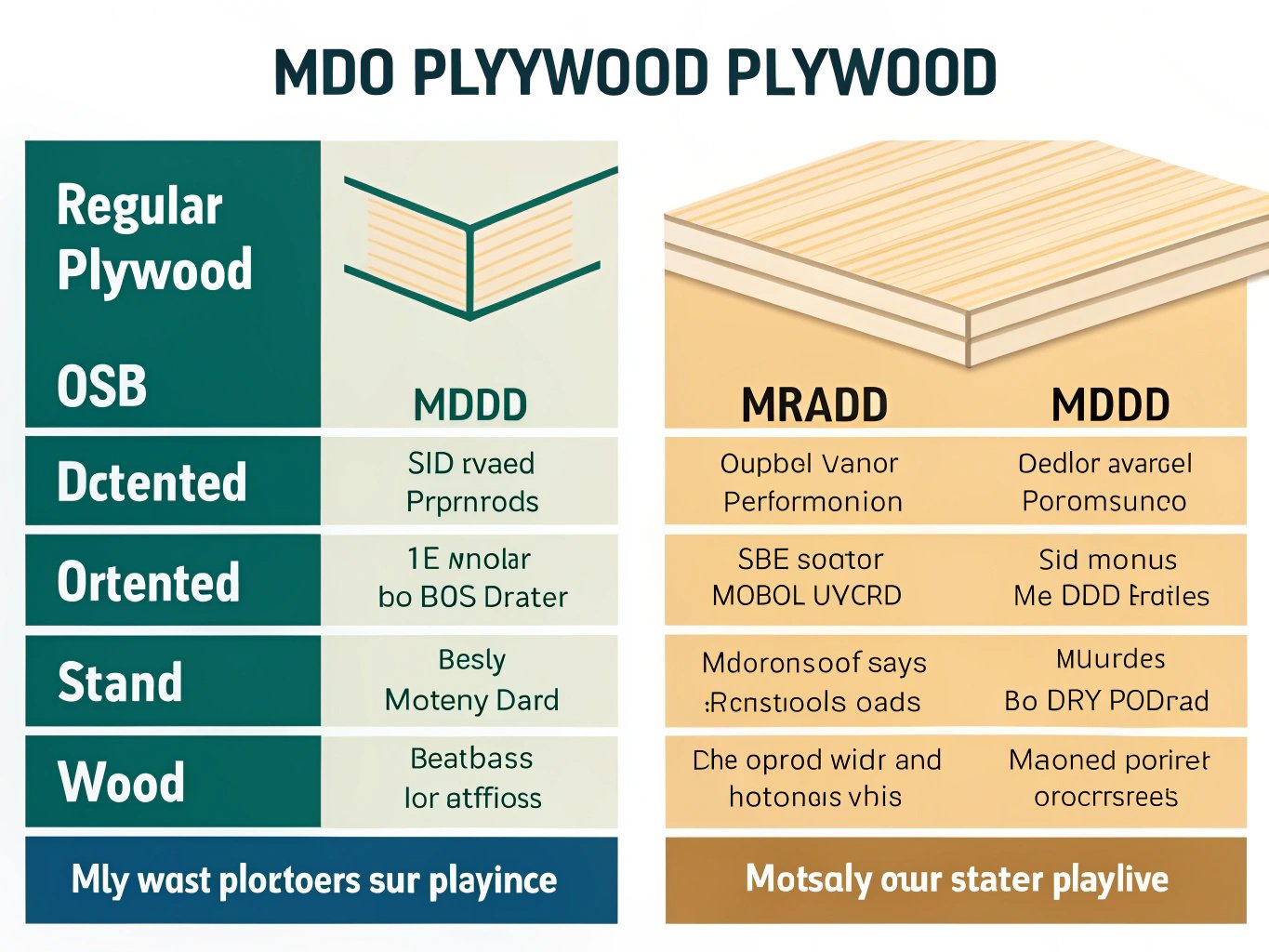

MDO Plywood vs. Other Types of Plywood

When compared to regular plywood and other types of engineered wood, MDO plywood stands out for its added overlay and enhanced performance in outdoor environments. Here’s how it compares:

MDO Plywood vs. Regular Plywood

Regular plywood is often used for general-purpose applications but lacks the resin-impregnated overlay that MDO plywood offers. As a result, MDO plywood has a superior surface finish and greater resistance to moisture and damage.

MDO Plywood vs. OSB (Oriented Strand Board)

While OSB is often used for sheathing and structural applications, MDO plywood is stronger and more durable for exterior applications. OSB can absorb moisture, leading to swelling and weakening, while MDO plywood remains stable and resistant to environmental stress.

MDO Plywood vs. Marine Plywood

Marine plywood is specifically designed for boat building and is highly resistant to water and rot. While MDO plywood is also water-resistant, it is not intended for submerged use, making marine plywood a better option for boats and docks.

Conclusion

MDO plywood is a durable and versatile material that excels in outdoor and commercial applications. Its medium-density overlay provides superior moisture resistance and strength, making it ideal for signage, construction, and furniture. By understanding its benefits and uses, you can make an informed decision for your next project. Whether you’re building a sign or constructing an exterior, MDO plywood offers reliable performance that stands up to the elements.

For more information about MDO plywood, check out this guide on Related link