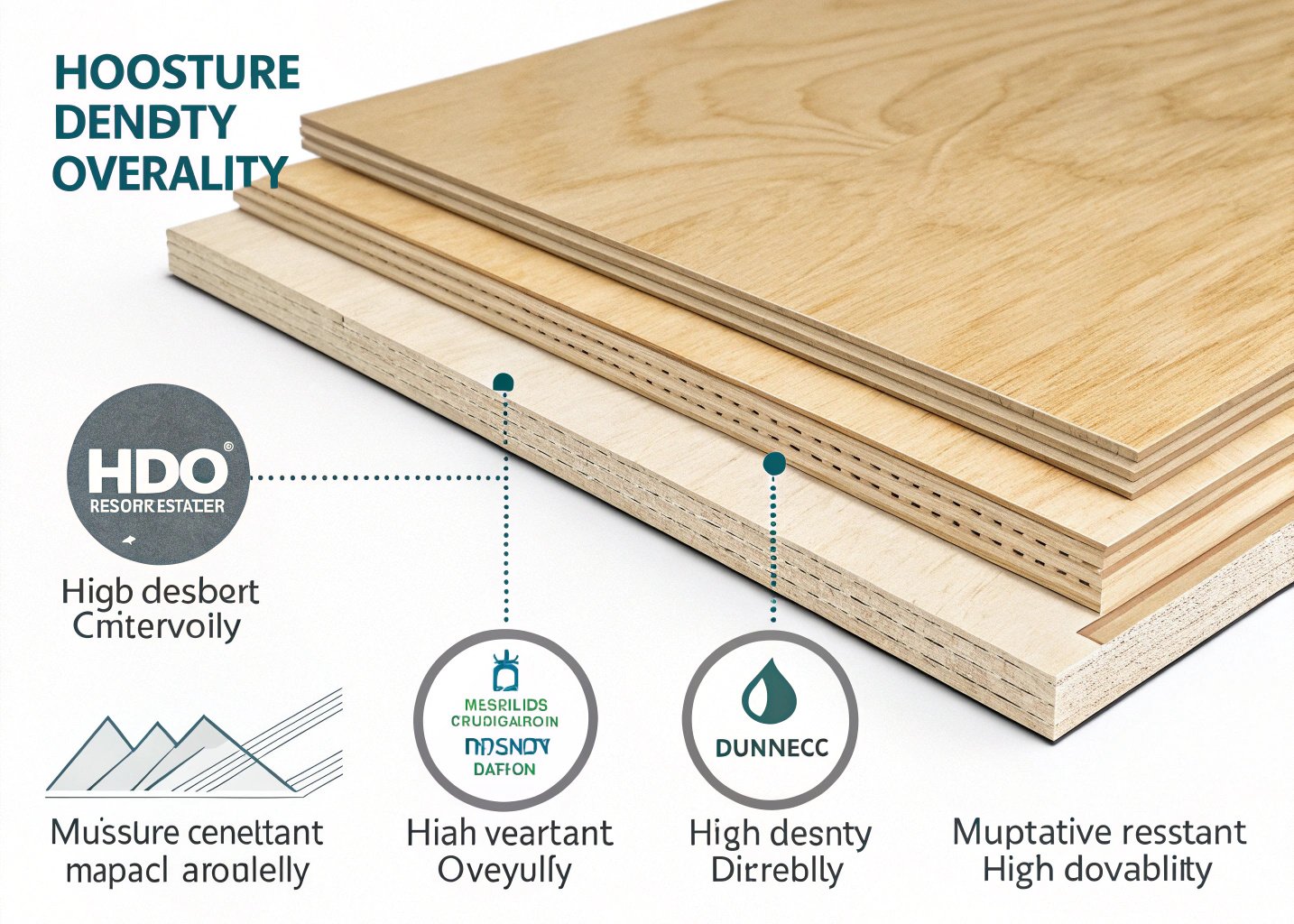

HDO plywood is a durable, high-density overlay plywood used in various industries for applications that require moisture resistance and high-impact durability. Let’s explore what makes it unique and how it can be utilized.

HDO plywood, also known as High-Density Overlay plywood, offers superior strength, moisture resistance, and versatility for heavy-duty applications. Learn how to choose and use HDO plywood in your projects.

HDO plywood (High-Density Overlay) is a specialized type of plywood that has a tough, smooth surface layer bonded to its core, making it resistant to water, impacts, and wear. This plywood variant is widely used in industries where strength and durability are essential, especially in construction, transportation, and manufacturing. If you’re working on a project that requires a robust and long-lasting material, understanding HDO plywood and its applications can help you choose the right product.

✔

HDO plywood is designed with a high-density overlay that makes it moisture-resistant, which is why it’s often used in outdoor or damp environments.

✖

While HDO plywood is used in flooring in some cases, its applications extend beyond that, including in concrete forming, signage, and industrial uses.

What Is HDO Plywood?

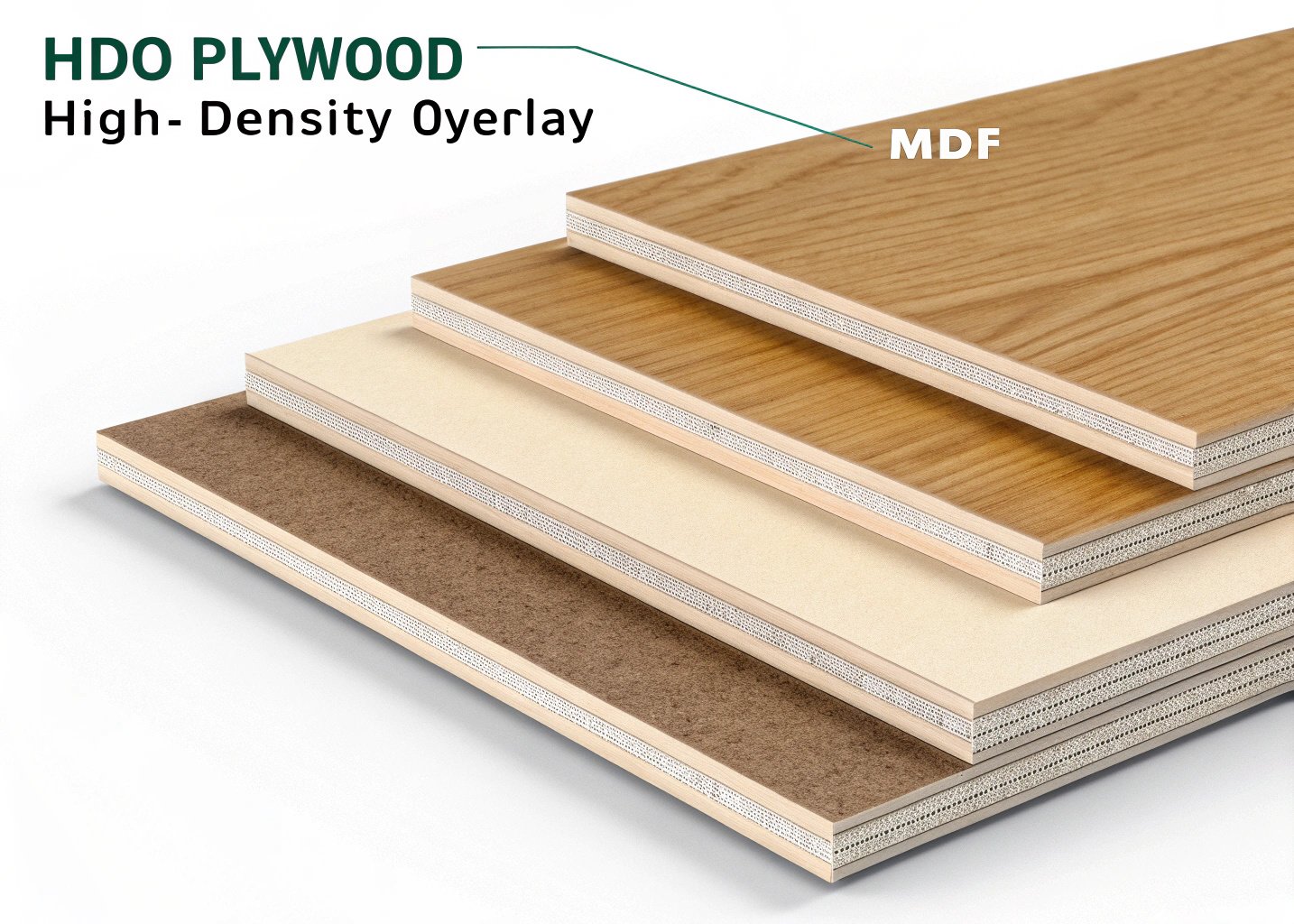

HDO plywood stands for High-Density Overlay plywood, a product that features a smooth, resin-impregnated surface layer bonded to a regular plywood core. This surface provides excellent protection against abrasion, impact, and moisture, making it ideal for demanding environments. The plywood itself is often constructed from layers of wood veneer, with the overlay material typically consisting of phenolic resin-treated paper or a similar material, which adds to its durability.

HDO plywood is often confused with MDF or other types of plywood, but its standout feature is its high-density surface, which ensures better wear resistance and a longer lifespan. It is commonly used in applications that require a high degree of durability and resilience.

Characteristics of HDO Plywood

HDO plywood is recognized for its specific properties that make it suitable for heavy-duty and industrial applications. Some of its key characteristics include:

Smooth and Durable Surface: The high-density overlay gives HDO plywood a smooth, glossy surface, making it resistant to wear and tear.

Moisture Resistance: The surface overlay significantly enhances moisture resistance, allowing the plywood to withstand exposure to water, making it ideal for outdoor applications.

Impact and Abrasion Resistance: HDO plywood’s dense surface is highly resistant to impact and abrasions, making it a perfect material for heavy-duty use.

High Strength-to-Weight Ratio: Although durable, HDO plywood is relatively lightweight compared to other materials with similar strength properties, making it easier to handle during construction and installation.

Customizable Sizes: HDO plywood is available in various thicknesses and sizes, which provides flexibility for different types of projects.

Benefits of HDO Plywood

Using HDO plywood offers several benefits, particularly in environments that demand high performance. These include:

Long-lasting Durability: Thanks to its tough surface, HDO plywood is capable of withstanding significant wear and tear over time.

Enhanced Aesthetics: The smooth surface not only improves the strength but also enhances the appearance, making it suitable for visible applications.

Cost-Effective: HDO plywood is generally more affordable than some of the other high-performance materials with similar properties, making it a budget-friendly choice for heavy-duty uses.

Environmental Resistance: The moisture-resistant properties make it perfect for use in regions with high humidity or for applications where exposure to water or chemicals is likely.

Applications of HDO Plywood

HDO plywood is used across various industries and for many types of construction projects. Here are some of its most common applications:

Concrete Forming

HDO plywood is frequently used in the construction industry, particularly for concrete forming. It provides a smooth and durable surface for molding concrete walls, floors, and other structures. The high-density overlay ensures that the plywood resists wear from the abrasive nature of wet concrete, and it can be reused multiple times in forming applications.

Truck and Trailer Flooring

Due to its durability and moisture resistance, HDO plywood is an excellent choice for truck and trailer flooring. The material can withstand heavy loads, impacts, and moisture, making it perfect for vehicles that transport goods under varying weather conditions.

Exterior Signage

The weatherproof nature of HDO plywood makes it ideal for outdoor signage. Its ability to resist water and UV rays ensures that signs remain in good condition over time, even when exposed to the elements.

Industrial Use

HDO plywood is also used in the manufacturing of industrial equipment, such as loading docks, scaffolding, and forms for precast concrete production. Its high strength, moisture resistance, and abrasion resistance are key factors in these demanding applications.

Packaging and Crating

In industries where goods need to be securely transported or stored, HDO plywood is often used for custom crates and packaging. The material is strong enough to handle heavy products while protecting them from damage during transit.

Elevator Panels and Cab Interiors

The smooth surface of HDO plywood makes it a preferred material for elevator paneling and interior construction. The durability and aesthetic qualities ensure a long-lasting finish for areas that require both functionality and appearance.

Furniture and Cabinet Making

Although not as common as other wood products, HDO plywood is sometimes used in furniture making, particularly for pieces that require additional strength and a smooth, durable surface. Its resistance to wear makes it a great option for high-use areas like tabletops and shelves.

How to Choose HDO Plywood for Your Project

When selecting HDO plywood for your specific application, here are a few considerations to keep in mind:

Thickness: Choose the thickness of the plywood based on the load it needs to bear and the durability required. Common thicknesses for HDO plywood range from 1/4 inch to 3/4 inch.

Surface Grade: The quality of the overlay can vary. Choose a higher-grade plywood if aesthetics are important, or a more utilitarian grade if performance is the primary focus.

Environmental Factors: If the plywood will be exposed to extreme conditions (e.g., heavy moisture or harsh chemicals), make sure to choose a grade of HDO plywood that is specifically designed for those environmental conditions.

Size: Ensure that the plywood sheets you choose are the right size for your project to avoid excessive cutting or waste.

Conclusion

HDO plywood is an incredibly versatile and durable material that offers a range of benefits for demanding construction, industrial, and commercial applications. Its ability to withstand moisture, impact, and abrasion makes it an ideal choice for concrete forming, truck flooring, signage, and more. By understanding its characteristics and applications, you can make an informed decision on whether HDO plywood is the right material for your next project. Whether you’re working on construction, manufacturing, or outdoor signage, HDO plywood’s strength and durability can help you achieve lasting results.