Choosing the right plywood can be confusing due to its different types and grades. This guide helps you understand these differences and choose the best plywood for your project.

Understanding plywood types and grades is crucial for selecting the right material for your project. Learn about the differences between types and grades and how to choose the best option for your needs.

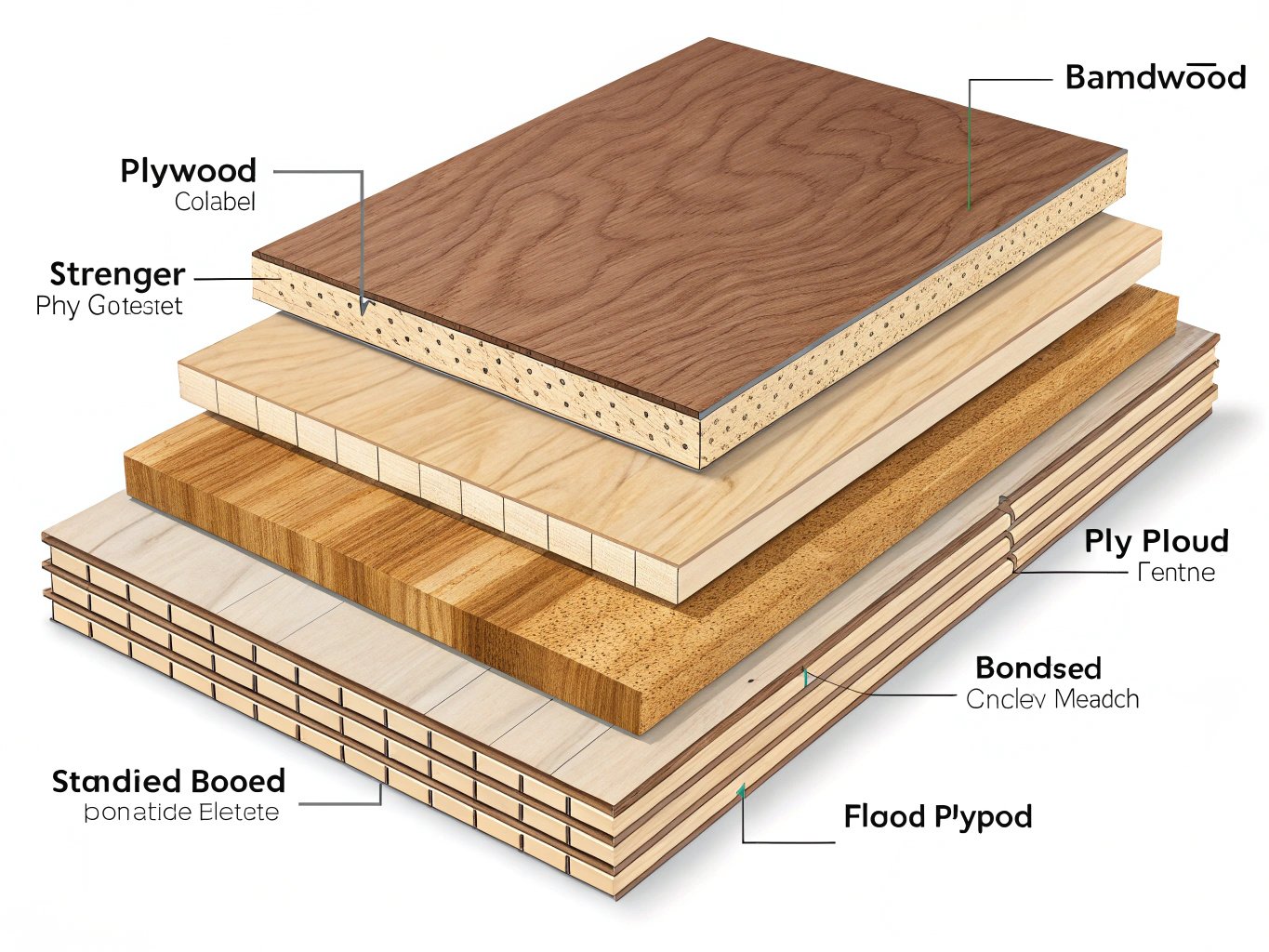

When embarking on a construction or woodworking project, understanding plywood is crucial. Plywood is a versatile, cost-effective material used for everything from furniture to flooring, and knowing which type and grade of plywood to choose can greatly affect your project’s success. Plywood comes in many forms, each with unique features that make it better suited for specific applications. In this guide, we’ll dive deep into the different types and grades of plywood to help you make the best decision for your needs.

✔

Not all plywood is made with three layers. Most plywoods are made with an odd number of layers, with some types featuring more than three for additional strength and support.

✖

Higher-grade plywood has fewer defects, more layers, and smoother surfaces, providing greater durability and aesthetic appeal.

What Are the Different Types of Plywood?

Plywood is made from layers, or veneers, of wood glued together to create a stronger material. The most common types of plywood are made from either softwood or hardwood, but other special types of plywood exist for specific applications.

Softwood Plywood

Softwood plywood is one of the most widely used types. Made from coniferous trees, such as pine, fir, or spruce, it’s a staple in construction projects due to its strength and cost-effectiveness. Softwood plywood is typically used for applications like flooring, sheathing, and subflooring. Its primary advantage is its strength-to-weight ratio, which makes it easy to handle and affordable without sacrificing much durability.

However, while softwood plywood is great for general use, it is not ideal for projects that will be exposed to moisture. It’s not treated for water resistance, so prolonged exposure to moisture can lead to warping and damage over time.

Hardwood Plywood

Hardwood plywood, on the other hand, is made from deciduous trees, such as oak, maple, and birch. These types of plywood are typically used for applications that require strength and aesthetic appeal, such as furniture, cabinets, and interior paneling. Hardwood plywood is known for its superior durability and resistance to wear and tear. It also offers a smooth surface that is perfect for staining or painting, making it a favorite for visible or decorative projects.

While hardwood plywood is often more expensive than softwood plywood, its longevity and overall quality make it a good investment for projects that need to stand up to heavy use or require a polished finish.

Marine Plywood

Marine plywood is a specialized type designed to handle environments with high moisture levels. It’s made from durable hardwoods and treated with waterproof adhesives, making it ideal for boat building, docks, or any outdoor structure exposed to constant water. Marine plywood is constructed with no gaps or voids, preventing water from seeping into the layers and causing rot. It’s treated to resist fungi, mold, and other forms of decay.

However, marine plywood is one of the most expensive types due to its high resistance to water damage. For that reason, it is typically used in situations where water exposure is constant and unavoidable.

Exterior Plywood

Exterior plywood is designed for outdoor use but isn’t completely waterproof like marine plywood. This type of plywood is treated with weather-resistant adhesives, which allow it to withstand exposure to moisture and temperature fluctuations. Exterior plywood is commonly used in siding, roofing, and decking applications, but it should not be submerged in water or exposed to prolonged moisture.

While it’s a more affordable option than marine plywood, exterior plywood is still much stronger than regular interior plywood, making it a solid choice for many outdoor construction projects.

Interior Plywood

As the name suggests, interior plywood is made for indoor use and is not designed to withstand moisture or harsh weather conditions. It is typically used for furniture, wall paneling, and shelving. Interior plywood comes in different grades, with higher-grade options offering smoother surfaces and fewer defects. It’s an affordable and reliable material for indoor projects where aesthetics and ease of work are a priority.

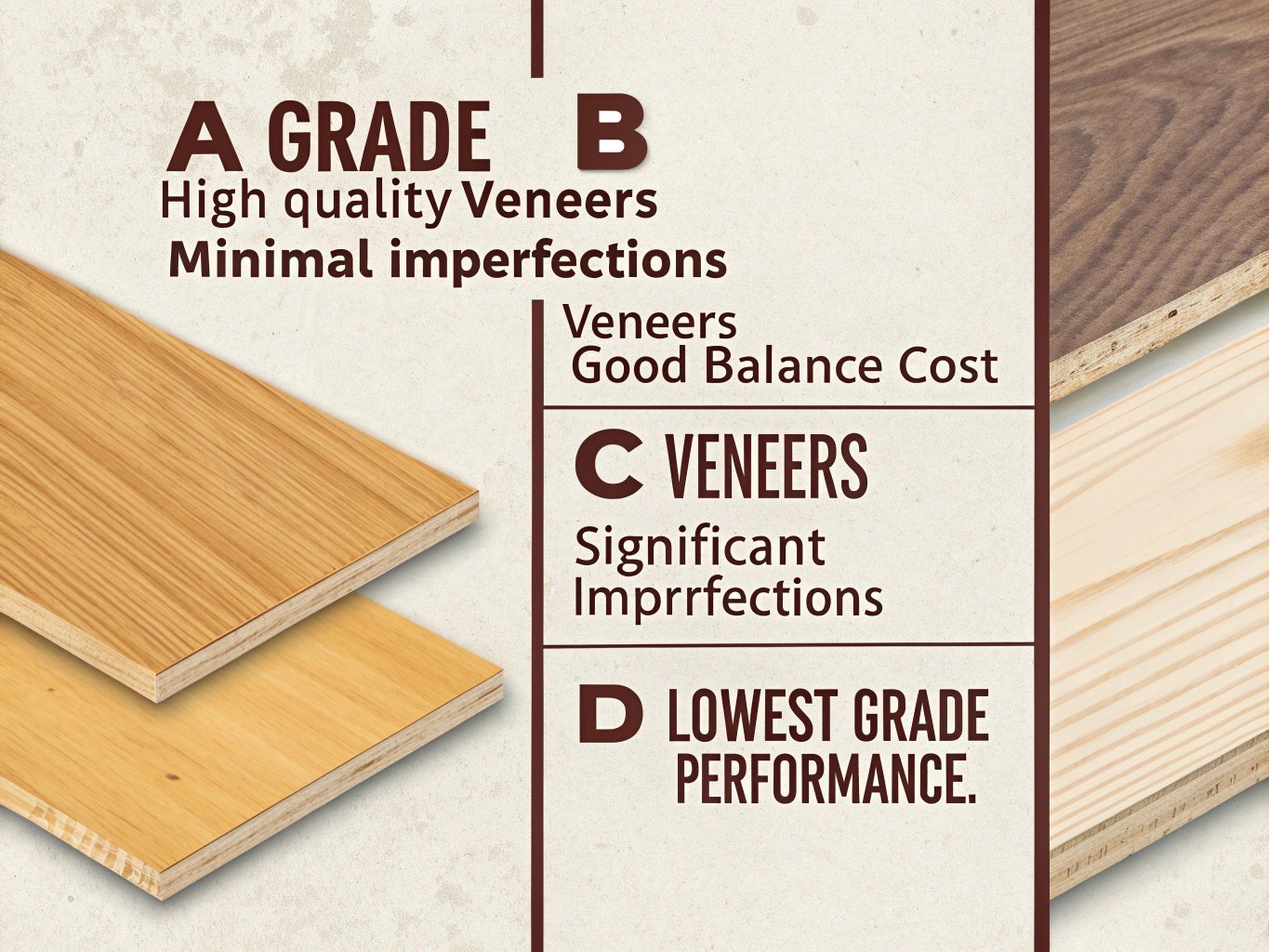

Understanding Plywood Grades

Plywood comes in different grades, which refer to the quality of the veneers used, as well as the number of imperfections present. The grade of plywood impacts its strength, appearance, and performance, and understanding these grades is key to selecting the best plywood for your project.

Plywood is typically graded with letters, where “A” represents the highest quality and “D” the lowest. These grades give you a good idea of what to expect in terms of aesthetics and functionality.

Grade A

Grade A plywood is the highest quality, featuring a smooth surface with minimal imperfections. It is the ideal choice for projects where appearance is crucial, such as furniture making, cabinetry, and other decorative applications. Plywood of this grade has very few knots and no discolorations, making it perfect for visible surfaces.

Grade B

Grade B plywood is still of high quality but may have more visible imperfections than Grade A plywood. These imperfections are usually small knots or patches that don’t significantly affect the strength or performance of the plywood. Grade B plywood is often used for projects where the plywood will not be prominently visible, such as for interior walls or cabinetry that will be painted.

Grade C

Grade C plywood has more noticeable defects and imperfections, such as knots, gaps, and discoloration. While it’s still relatively strong, it may require some sanding or filling to ensure a smooth finish. Grade C plywood is often used for structural applications or for projects where the plywood will be hidden or covered by other materials.

Grade D

Grade D plywood is typically used for structural purposes where appearance is not a concern. It has the most imperfections and is often used in subflooring, roofing, and other hidden construction applications. Grade D plywood is the most affordable option but comes with the trade-off of a less refined appearance.

Special Grades

Some plywoods come with special grade markings such as "CDX" plywood. The "C" and "D" refer to the grades of the front and back veneers, while the "X" signifies that the plywood is treated with waterproof adhesive. CDX plywood is often used for exterior sheathing, subflooring, and other structural applications.

How to Choose the Right Type and Grade of Plywood

Choosing the right plywood for your project comes down to understanding both the type and grade of plywood that best suits your needs. If you’re working on an outdoor construction project that will be exposed to weather and moisture, then exterior plywood or marine plywood is your best bet. These types are designed to resist the elements and last longer in harsh conditions.

For indoor projects where appearance matters, such as furniture or cabinetry, hardwood plywood or grade A plywood should be your top choice. These offer the best appearance and performance for projects where you want a smooth, high-quality finish.

For structural applications, such as subflooring or roofing, consider using structural plywood or CDX plywood. These are built to provide the strength and durability necessary for heavy-duty applications.

Types of Plywood and Their Uses

Different types of plywood are suited to different applications. Whether you’re building furniture, constructing a house, or working on a DIY project, understanding the specific features and applications of each type of plywood can help you choose the right one for your needs.

| Type of Plywood | Common Uses |

|---|---|

| Softwood Plywood | Subflooring, sheathing, general construction |

| Hardwood Plywood | Furniture, cabinetry, decorative applications |

| Marine Plywood | Boat building, docks, exterior structures in wet environments |

| Exterior Plywood | Siding, decking, roofing, outdoor structures |

| Interior Plywood | Furniture, wall paneling, shelving |

Conclusion

Understanding the different types and grades of plywood is essential for choosing the best material for your project. Whether you need plywood for construction, furniture making, or something in between, knowing the right type and grade will ensure that you get the best performance and aesthetic for your needs. Take your time to assess the requirements of your project before selecting the plywood that’s right for you.