Wondering what makes exterior rated plywood different? This guide will explain why it’s essential for outdoor projects and how to choose the best type.

- Exterior-rated plywood is specially engineered to withstand outdoor conditions, providing enhanced durability, moisture resistance, and structural integrity for various construction projects. This type of plywood is typically used for applications exposed to the elements, such as decking, roofing, and siding, where protection from water, humidity, and temperature fluctuations is crucial. Its treatment and material composition ensure that it can endure harsh weather conditions, including rain, snow, and heat, without losing strength or shape. By using exterior-rated plywood, builders can ensure long-lasting, reliable performance, while minimizing the risk of warping, rotting, or degradation over time. Whether for residential, commercial, or industrial purposes, exterior-rated plywood offers a versatile and cost-effective solution for outdoor applications..

-

If you’re planning an outdoor construction project, understanding the differences between interior and exterior rated plywood is crucial. Let’s dive into why exterior rated plywood should be your go-to material.

✔

Exterior rated plywood is treated to resist moisture, but prolonged exposure to water can still cause damage. It is not entirely waterproof.

✖

Exterior rated plywood is specifically designed for outdoor applications like decking, roofing, and siding, not for indoor furniture or dry environments.

What Is Exterior Rated Plywood?

Exterior rated plywood, also known as exterior-grade plywood, is a type of plywood designed to be more resistant to the elements compared to standard interior plywood. Unlike interior plywood, which is primarily intended for indoor use, exterior plywood is treated to withstand moisture, humidity, and temperature fluctuations. It is often used for outdoor construction applications, such as roofing, siding, decks, and other exposed areas of buildings.

Exterior rated plywood is typically bonded with waterproof adhesive, and the wood used is usually of a higher quality to ensure that the plywood can handle the stress of outdoor conditions. It is crucial for ensuring long-term durability and stability in outdoor structures.

The Role of Adhesive in Exterior Plywood

The adhesive used to bind exterior plywood plays a significant role in its durability. The most common adhesive for exterior plywood is phenolic resin, which is highly water-resistant and ensures that the plywood stays intact even in wet conditions. This makes exterior rated plywood ideal for areas that are exposed to moisture, such as exterior walls or underlayment for roofing.

For more detailed information on adhesives used in plywood, check out this comprehensive guide on plywood adhesives

Why Choose Exterior Rated Plywood?

Choosing exterior rated plywood is essential for ensuring the longevity of your outdoor construction projects. Here’s why:

Weather Resistance

Exterior rated plywood is designed to withstand the harsh conditions of outdoor environments, including rain, humidity, and extreme temperatures. The waterproof adhesives and treated wood ensure that the plywood doesn’t swell, warp, or deteriorate over time, making it ideal for decking, roofing, and siding.

Durability

Compared to interior plywood, exterior plywood is built to last longer when exposed to the elements. It can handle heavy-duty applications such as building exterior walls, sheathing, and temporary structures like scaffolding.

Cost-Effective

While exterior rated plywood can be more expensive than interior plywood, it provides long-term value due to its increased durability. You’ll spend less on repairs and replacements, making it a worthwhile investment for outdoor projects.

Versatility

Exterior plywood is suitable for a variety of applications, from building outdoor furniture to constructing garden sheds. It can also be used for projects like pools, playgrounds, and even fencing.

Types of Exterior Rated Plywood

There are several types of exterior rated plywood, and each serves a different purpose depending on the project. Here are the most common types:

Marine Grade Plywood

Marine grade plywood is a high-quality type of exterior plywood designed for use in environments with constant exposure to moisture, such as boat building or other water-related applications. It’s treated to resist rot and fungal growth and is manufactured with higher standards for durability. It is the most expensive type of exterior plywood, but it’s ideal for projects that will be in constant contact with water.

CDX Plywood

CDX plywood is a popular and cost-effective choice for general construction purposes, especially for exterior sheathing. It is typically made from softwood species and has a lower grade than marine-grade plywood. The "CDX" classification refers to the type of veneer used in the plywood’s surface. It’s commonly used for roofing, subflooring, and walls. Although it’s water-resistant, it’s not entirely waterproof, so it’s best used in applications that won’t be exposed to constant moisture.

For more information about marine grade plywood, see this guide to choosing marine-grade plywood.

Pressure-Treated Plywood

Pressure-treated plywood is another option for outdoor use. The plywood is treated with chemicals under high pressure to make it resistant to decay, rot, and insect damage. It is commonly used for decking, fences, and garden structures where the wood is exposed to moisture and outdoor elements.

How to Identify Exterior Rated Plywood

Knowing how to identify exterior rated plywood is essential for making sure you’re selecting the right material for your project. Here are a few key indicators to look for:

Markings and Labels

Exterior plywood often has markings on the edge or surface to indicate its grade and suitability for outdoor use. Look for labels that indicate "Exterior," "CDX," or "Marine Grade." These markings will tell you that the plywood has been specifically designed for outdoor applications.

Thickness

Exterior plywood is available in a range of thicknesses, from 1/4 inch to 3/4 inch and beyond. The thicker the plywood, the more durable and stable it will be for construction applications.

Grain Pattern

Check the grain pattern of the plywood. Exterior plywood will generally have a more uniform grain, and the veneers should be free from voids or large knots. The higher the quality of the wood used in the plywood, the more durable it will be in the long run.

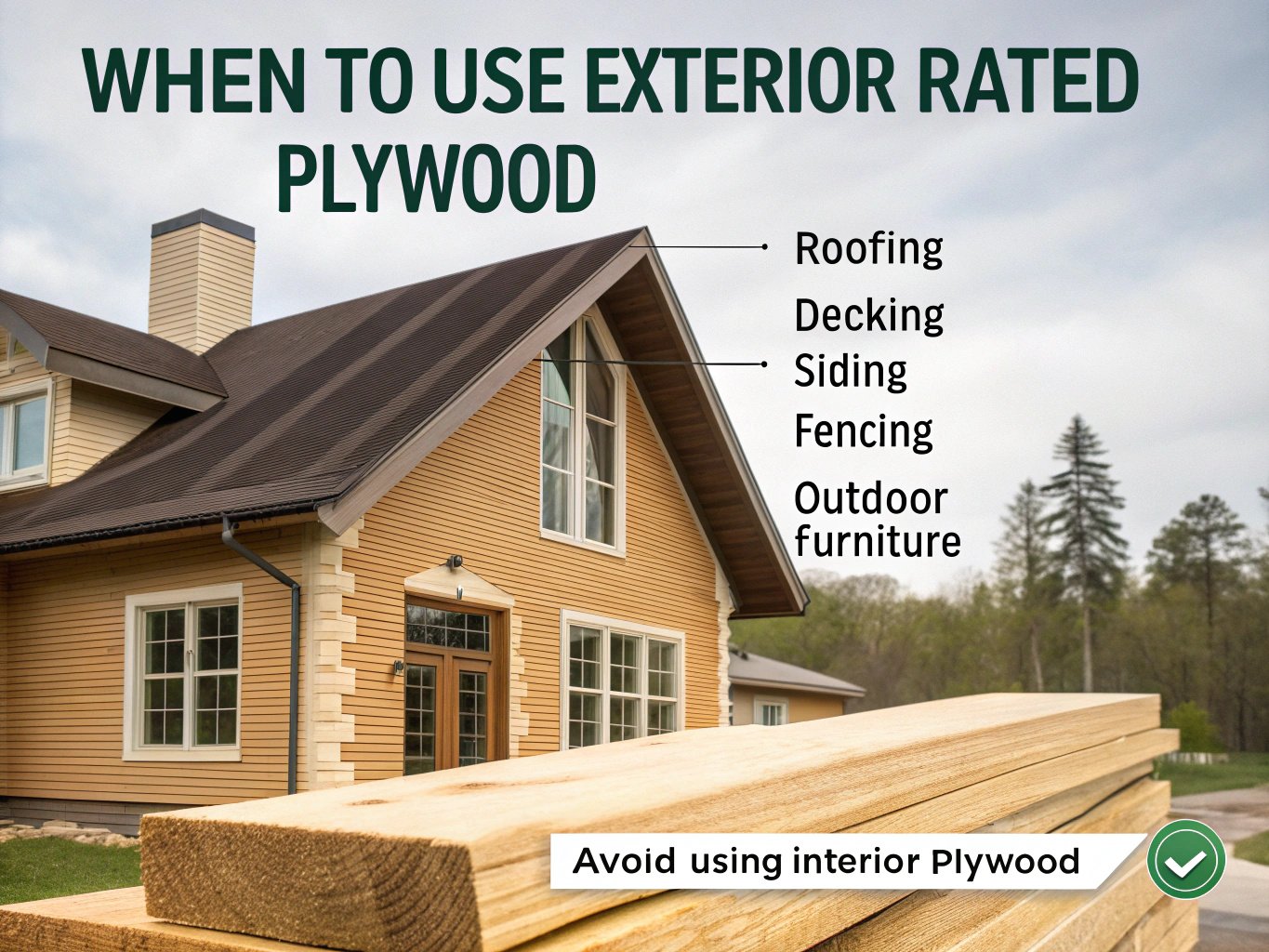

When to Use Exterior Rated Plywood

You should always use exterior rated plywood when working on outdoor construction projects where the plywood will be exposed to moisture, such as:

- Roofing

- Decking

- Siding

- Fencing

- Outdoor furniture

Avoid using interior plywood for any outdoor applications, as it is not designed to withstand the environmental conditions that exterior plywood can handle.

Conclusion

Exterior rated plywood is essential for outdoor projects because of its durability, moisture resistance, and ability to withstand the elements. Whether you’re building a deck, installing siding, or constructing a garden shed, using the right type of plywood ensures that your project will stand the test of time. By understanding the types of exterior rated plywood available and how to properly identify it, you’ll be well on your way to completing a successful outdoor project.