Not every floor needs plywood underlayment—but when it does, skipping it can lead to cracks, noise, or flooring failure.

Use plywood underlayment when installing vinyl, laminate, or engineered flooring over uneven subfloors to provide a smooth, stable surface.

Plywood underlayment sits between the structural subfloor and your finished floor. It helps smooth out surface imperfections, supports softer flooring, and improves sound insulation. But it’s not always required, and the wrong type or installation method can cause more harm than good. In this guide, we’ll cover when to use underlayment, what type to choose, and how to lay it the right way.

When to use plywood underlayment?

It’s not used in every floor system—but some materials need it to perform well.

Use plywood underlayment when installing resilient floors like vinyl, linoleum, or glue-down carpet, especially if the subfloor has seams, knots, or voids.

Subfloors made of OSB or standard plywood may have fasteners, dips, or joint seams that telegraph through thin finish flooring. Underlayment creates a uniform layer for glue adhesion or floating floor support. It’s also important for soft flooring that might dent or flex. In some cases, like click-lock vinyl plank over new plywood, underlayment may not be necessary—but always follow the flooring manufacturer’s requirements.

Does it matter what underlayment you use?

Yes—flooring success often depends on picking the right material beneath the finish layer.

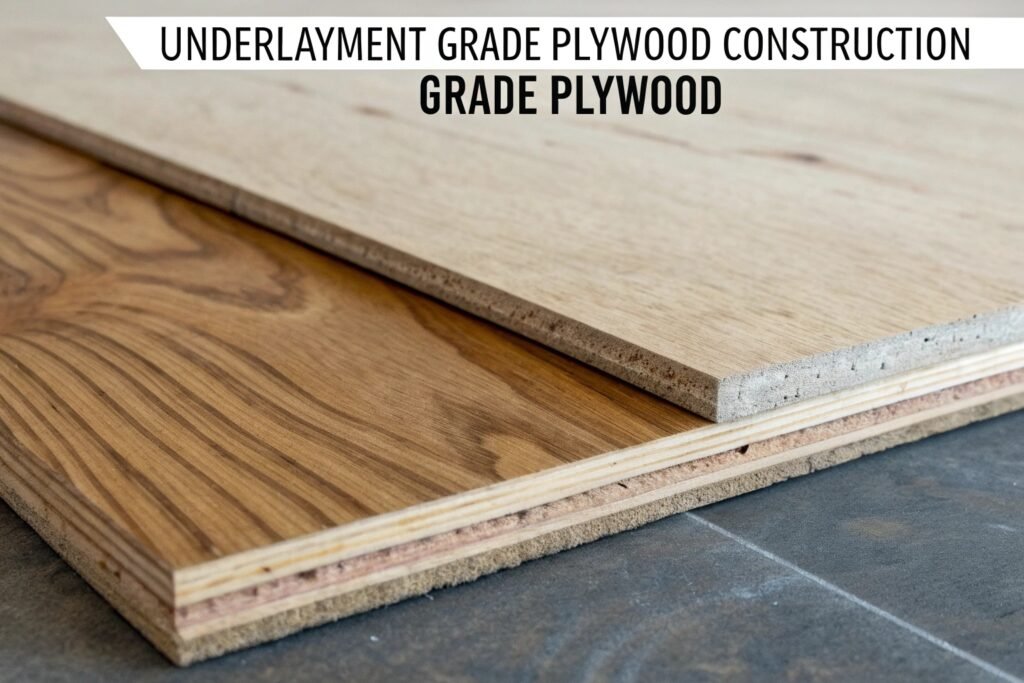

It absolutely matters—use underlayment-grade plywood (such as 1/4" lauan or hardwood-faced panels) that’s smooth, void-free, and designed for flooring.

Not all plywood is suitable for underlayment. Construction-grade panels may have internal voids, raised grain, or rough patches that cause lumps under thin flooring. Use panels labeled “floor underlayment” or “APA underlayment,” which are made with tighter core construction and smoother faces. Avoid MDF or particle board—they swell when exposed to moisture. For tile or stone floors, use cement board instead of wood underlayment to prevent cracking.

Does it matter which way you lay plywood underlayment?

Yes—orientation affects both strength and stability.

Lay plywood underlayment perpendicular to the floor joists, with staggered seams, and leave small gaps for expansion.

Just like subfloor panels, underlayment must be laid with the face grain perpendicular to joists for maximum strength. Stagger seams so that four corners never meet in one place. Leave a 1/16" gap between panels and 1/8" around the room perimeter to allow for expansion. Fasten with ring-shank nails or underlayment staples every 4–6 inches along the edges and 6 inches in the field. Don’t glue it unless the manufacturer specifies.

Should I use 5/8" or 3/4" plywood for subfloor?

Subfloor thickness affects everything from bounce to flooring life span.

3/4" plywood is better than 5/8" for subflooring due to greater strength, reduced flex, and better screw holding.

5/8" plywood (15.88 mm) may meet code for closely spaced joists but tends to flex more, leading to squeaks or tile cracks. 3/4" plywood (18–19 mm) offers better rigidity and is more compatible with modern finish flooring. If you’re adding underlayment on top, ensure the total thickness doesn’t interfere with door clearance or transitions. When in doubt, go thicker for long-term stability and comfort.

Conclusion

Plywood underlayment smooths subfloor imperfections and supports soft or sensitive floor coverings. Choose the right grade, install it with care, and match it to your flooring for a durable, quiet, and seamless surface.