Plywood is a common material used in construction and home projects. But when it comes to selecting the right type, you might wonder what sets CDX plywood apart from ACX plywood. Let’s explore the key differences and help you decide which one is best for your needs.

CDX plywood is primarily designed for outdoor use, offering durability and strength to withstand the elements, making it ideal for projects like roofing, sheathing, and exterior construction. It’s treated to resist moisture and has a rougher surface compared to other types of plywood. On the other hand, ACX plywood is typically used for interior applications, where a smoother, more aesthetically pleasing finish is needed. It’s commonly used in cabinetry, furniture making, and interior paneling, providing both structural integrity and an attractive surface. Understanding the key differences between CDX and ACX plywood—such as moisture resistance, surface finish, and application suitability—ensures that you choose the right material for your specific project needs, whether for outdoor durability or interior design..

When it comes to plywood for construction, choosing the right type can be confusing. Both CDX plywood and ACX plywood are commonly used materials, but they serve different purposes. CDX plywood is primarily used for exterior applications where exposure to moisture is likely, while ACX plywood is used for interior projects where appearance matters more. Let’s break down the distinctions to help you choose the best option for your needs.

✔

CDX plywood is a durable, exterior-grade plywood, specifically made to withstand moisture and weather, commonly used in roofing and wall applications.

✖

ACX plywood is intended for indoor use, often for furniture and cabinetry, and should not be exposed to direct moisture or outdoor conditions.

What is CDX Plywood?

CDX plywood is a type of exterior-grade plywood made with a combination of softwoods. The term CDX refers to the grade of the plywood, where C and D indicate the quality of the outer plies (the layers of wood on the top and bottom), and the X means that it is suitable for outdoor use with exposure to moisture. The surface quality may not be as smooth as other types of plywood, but CDX plywood is made to withstand the elements.

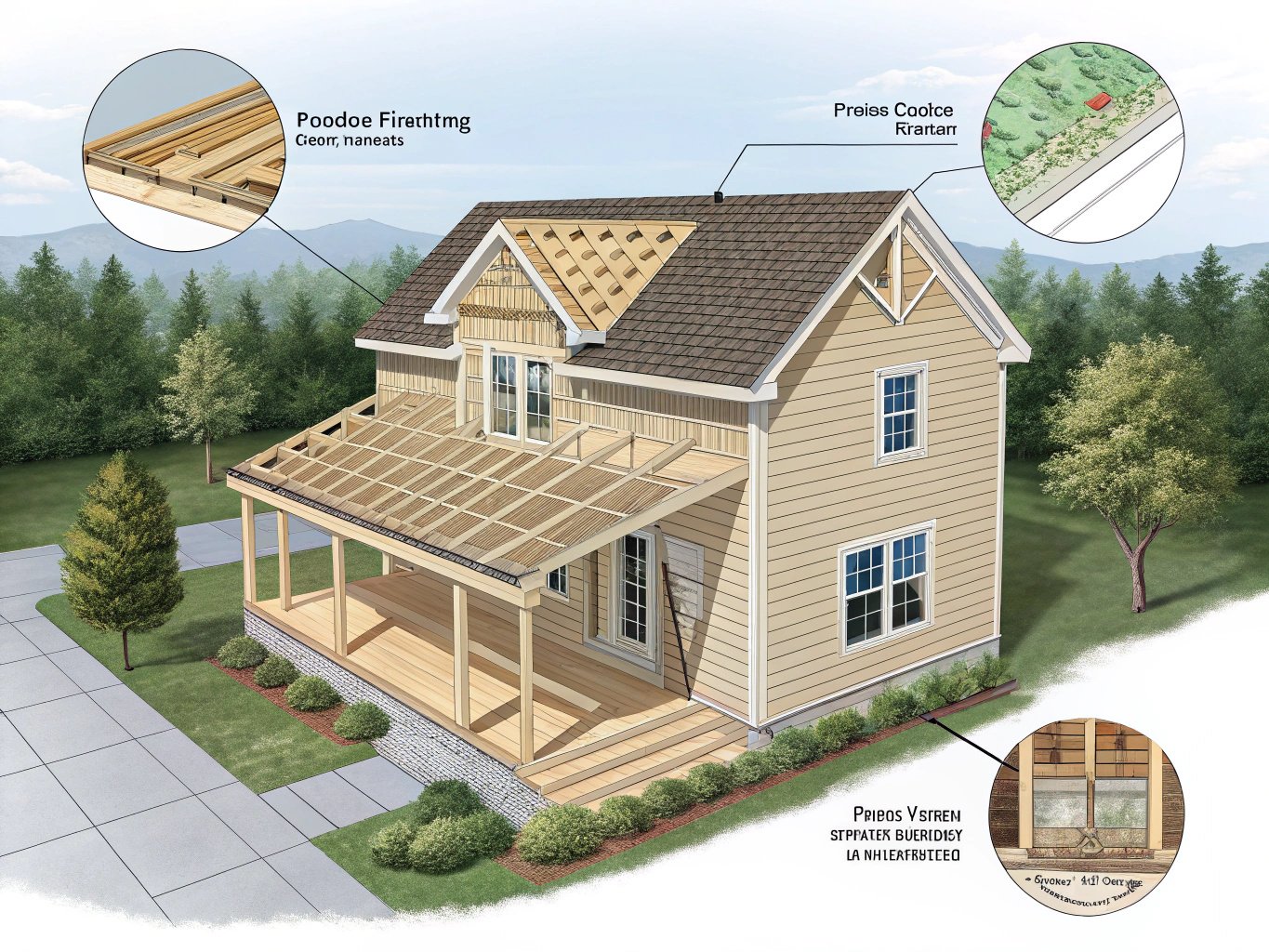

CDX plywood is commonly used for building applications like roofing, subflooring, and exterior wall sheathing. It is treated with water-resistant adhesive to prevent delamination, though it is not completely waterproof. It is best suited for environments where moisture exposure is moderate but not excessive.

CDX Plywood Characteristics:

- Grades: Typically graded as C-D, which indicates moderate-quality outer layers.

- Use: Ideal for structural applications like flooring, roofing, and walls.

- Treatment: Contains water-resistant adhesive but is not waterproof.

- Thickness: Available in 1/4", 3/8", 1/2", 5/8", and 3/4" thicknesses.

For more information on choosing the best exterior-grade plywood, check out this guide to CDX plywood.

What is ACX Plywood?

ACX plywood is an interior-grade plywood designed for applications where appearance is important. The A and C refer to the quality of the outer layers, with A being the highest grade (smooth and defect-free) and C being a lower grade (may contain small knots or blemishes). The X in ACX denotes that it has an exterior-grade adhesive, but it is intended for indoor use only. This plywood is often used in cabinetry, furniture, and other projects where a smooth, attractive surface is desired.

ACX plywood is perfect for projects that will be painted or veneered because the surface is smooth enough to allow for fine finishes. However, it is not recommended for outdoor applications due to its susceptibility to water damage.

ACX Plywood Characteristics:

- Grades: The surface is usually smooth and free from large defects (Grade A).

- Use: Perfect for cabinetry, furniture, and interior paneling.

- Treatment: Uses exterior-grade adhesive, but not suitable for outdoor exposure.

- Thickness: Available in similar thicknesses as CDX plywood, typically 1/4", 3/8", 1/2", and 3/4".

For more on choosing the right plywood for indoor projects, visit this guide to ACX plywood.

Differences Between CDX and ACX Plywood

The primary difference between CDX and ACX plywood lies in their intended use and quality:

| Characteristic | CDX Plywood | ACX Plywood |

|---|---|---|

| Grade | C-D (lower-quality outer layers) | A-C (high-quality smooth surface) |

| Moisture Resistance | Water-resistant, not waterproof | Not suitable for exposure to moisture |

| Best Use | Exterior applications (e.g., roofing, walls) | Interior applications (e.g., furniture, cabinetry) |

| Adhesive | Exterior-grade adhesive | Exterior-grade adhesive (for indoor use) |

| Surface Quality | Rough, with visible knots | Smooth, with minimal defects |

Key Takeaway: If you need plywood for an outdoor project, such as building a roof or exterior wall, CDX plywood is the right choice. For interior projects like furniture and cabinetry, where appearance and smoothness are crucial, ACX plywood is better suited.

When to Use CDX Plywood?

CDX plywood is perfect for structural applications in outdoor environments. Here are some common uses:

- Roof Sheathing: Used for covering roof frames before installing shingles or roofing materials.

- Flooring: Ideal for subflooring in homes and buildings exposed to moisture or humidity.

- Walls: Used as sheathing for exterior walls in homes and sheds.

It is an affordable and durable choice for projects that need to withstand the elements without being exposed to excessive moisture.

When to Use ACX Plywood?

ACX plywood is best suited for projects that need a smooth, high-quality surface and will not be exposed to outdoor elements. Here are a few examples:

- Cabinet Making: Ideal for creating interior cabinets with a smooth finish.

- Furniture: Used in constructing furniture pieces like tables, chairs, and bookcases.

- Paneling: Perfect for decorative interior wall paneling and woodwork.

Since it is designed for indoor use, ACX plywood is not recommended for areas prone to humidity or direct exposure to moisture.

Conclusion

Understanding the differences between CDX plywood and ACX plywood is crucial for choosing the right material for your project. CDX plywood is a great choice for outdoor structural applications, while ACX plywood is better suited for interior work where appearance is key. By selecting the appropriate type based on your needs, you can ensure that your project is durable, functional, and looks great.