Plywood is widely used in structural and decorative applications, and thickness is often assumed to determine strength or quality. However, thicker plywood is not always the better choice—it must match the intended function, environment, and installation method.

Thicker plywood offers more load capacity and stability but can be excessive, heavier, and harder to work with in certain contexts. The best plywood thickness depends on its structural purpose and application setting.

Factory usage considers not only thickness but also ply count, veneer quality, core type, and how it integrates into engineered systems.

When Does Thicker Plywood Provide Advantages?

In load-bearing, structural, or high-impact uses, thickness becomes essential. Greater rigidity and screw-holding strength are key advantages.

Flooring substrates, roofing panels, and heavy-duty cabinetry often rely on 18mm or thicker plywood for durability and performance.

| Application | Recommended Thickness |

|---|---|

| Subfloor Panels | 18–25 mm for deflection resistance |

| Wall Sheathing | 12–18 mm for wind load resistance |

| Furniture Bases | 15–18 mm for strength under load |

Factories processing thick plywood sheets use CNC routers, hydraulic clamps, and reinforced conveyors to handle added weight and resistance.

What Are the Downsides of Excessive Thickness?

Over-specifying plywood thickness leads to inefficiency, excess weight, and potential design conflicts.

Thicker plywood increases cost, limits flexibility in design, and adds handling complexity during manufacturing or installation.

| Drawback | Result |

|---|---|

| Added Weight | Difficult transport or lift installation |

| Higher Cost | Unnecessary material expenditure |

| Poor Flexibility | Limits use in curved or contoured elements |

Material selection in factory orders balances strength with cost-efficiency and downstream processing ease.

How Does Ply Count Affect Performance?

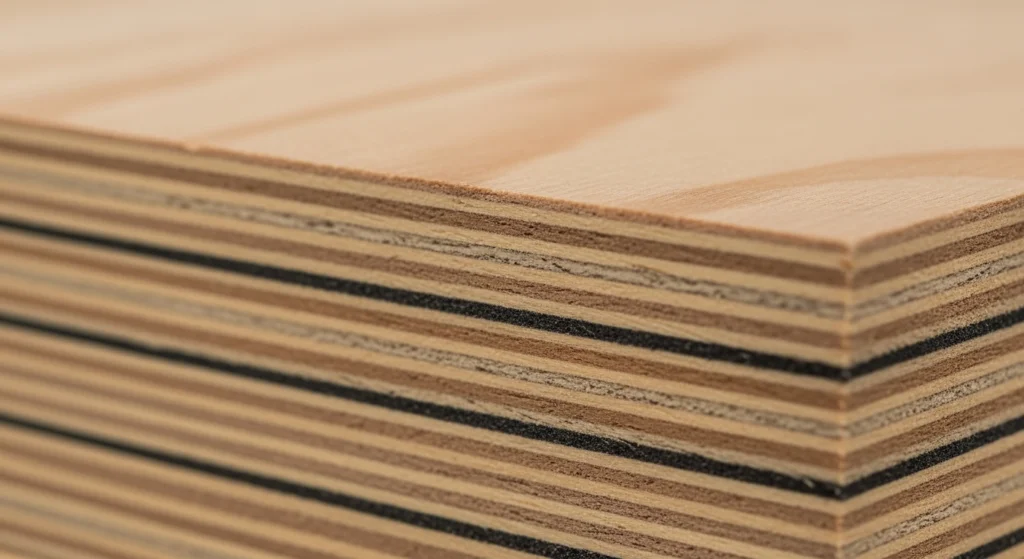

Thickness alone does not determine stability. A higher number of thinner plies offers better resistance to warping and delamination.

Plywood with more plies, even at similar thickness, provides better structural integrity than lower-ply equivalents.

| Ply Count | Advantage |

|---|---|

| 3-Ply | Lightweight, cost-effective, basic uses |

| 5–7 Ply | Balanced strength and dimensional stability |

| 9+ Ply | High-performance, minimal flex or failure |

Precision machines in factory lines assess both thickness and ply distribution when matching boards to customer project specs.

When Is Thinner Plywood the Better Choice?

Thinner plywood offers more flexibility, is easier to shape, and is ideal for non-load-bearing designs or detailed trim.

For drawer bottoms, cabinet backs, wall panels, or curved applications, thinner sheets provide efficiency and ease of use.

| Use Case | Typical Thickness |

|---|---|

| Drawer Bottoms | 3–6 mm |

| Interior Paneling | 6–9 mm |

| Furniture Skins | 3–5 mm |

Cutting stations in production facilities are often adjusted to handle thin sheets with high-speed scoring to avoid chipping or splintering.

How Do Factories Determine the Right Plywood Thickness?

Manufacturing environments select plywood thickness based on mechanical demands, installation location, and compatibility with joining systems.

Factory processes consider machine tolerances, fastener depth, panel size, and end-use requirements to recommend the most effective thickness.

| Consideration | Influence on Thickness Selection |

|---|---|

| Load Type | Determines structural thickness |

| Joinery Method | Affects how well screws or dowels hold |

| Finish Layer | May require thinner core under laminates |

Precision cutting, press forming, and packaging systems are calibrated to accommodate designated sheet thicknesses across bulk orders.

Conclusion

Thicker plywood is not always better. While it improves strength and rigidity, it can complicate manufacturing and raise costs. Performance depends on matching the correct thickness to the structural and aesthetic requirements of the project. Factories evaluate more than just thickness—ply count, density, and core quality also guide material decisions. The right choice balances durability, cost-efficiency, and production compatibility, ensuring optimal results across furniture, construction, and paneling applications.