Waterproofing plywood is essential for protecting it against moisture damage, ensuring longevity, and maintaining its structural integrity. Let’s explore the top methods for waterproofing plywood effectively.

Waterproofing plywood can help prevent warping, swelling, and mold growth caused by moisture exposure. Discover the top 5 methods to ensure your plywood remains protected and durable for years to come.

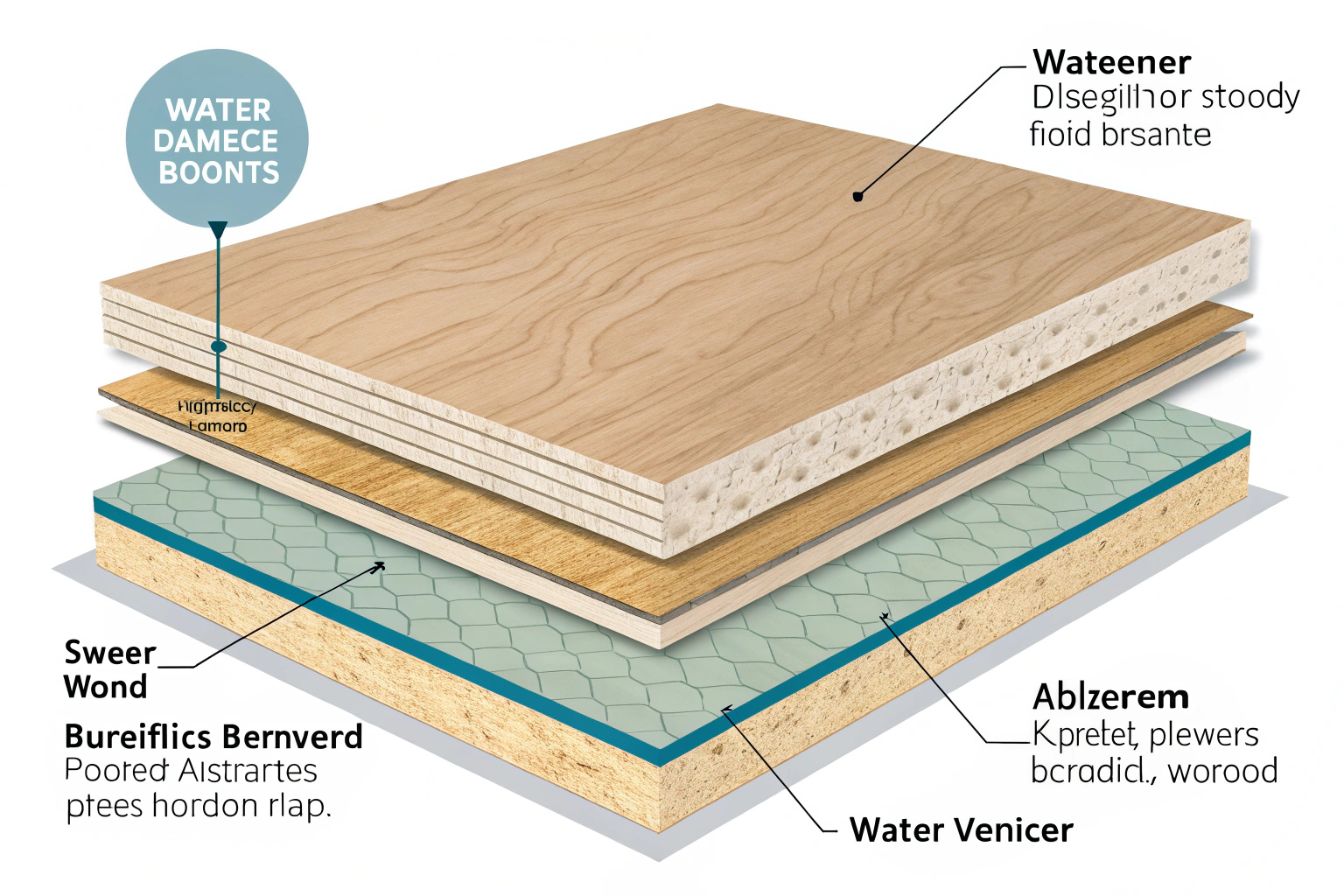

Plywood is widely used in both indoor and outdoor construction because of its affordability and versatility. However, its layered structure makes it prone to water damage if not properly sealed. Moisture can seep into the core, causing warping, swelling, and even rot. For projects that require long-term durability—like outdoor furniture, flooring, or kitchen cabinetry—learning how to waterproof plywood is not just helpful, it’s essential.

✔

Exposure to rain and humidity will damage unprotected plywood without waterproofing. Sealing extends its durability in outdoor environments.

✖

Some methods are surface-level and temporary, while others penetrate deeper into the wood, offering longer-lasting moisture protection.

Why Waterproofing Plywood Matters?

Plywood is made from layers of thin wood veneers bonded together with adhesive. While this construction gives it strength, it also means water can easily creep between the layers. Once water enters, the wood swells, weakens, and begins to separate. Even indoor spaces like kitchens and bathrooms can cause plywood to degrade over time due to high humidity.

If you’re using plywood in any area that’s even remotely exposed to moisture—whether that’s rain, condensation, or damp air—then waterproofing is a smart move. It protects your material investment, extends the life of your project, and prevents problems like mold or structural failure. For a detailed guide on wood swelling, The Spruce offers a great breakdown.

Method 1: Start with Waterproof Plywood?

One of the simplest ways to avoid moisture issues is to buy plywood that’s already made to resist water. Often labeled as “marine-grade” or “exterior-grade,” this type of plywood is treated with water-resistant adhesives during manufacturing. It’s specifically designed for wet environments and is often used in boat-building or exterior construction.

Using waterproof plywood saves time because it doesn’t require extra sealing. However, it tends to be more expensive than untreated plywood. For large-scale or long-term outdoor use—such as decking, exterior siding, or planter boxes—this investment is worth it. Wood Magazine provides a useful comparison between marine and exterior plywood.

Method 2: Use Polyurethane for Indoor Projects?

For interior plywood that might get damp but won’t be submerged—like shelving near a sink or bathroom cabinets—polyurethane is a great option. This clear coating creates a protective layer over the wood, blocking moisture while preserving the grain and color.

Applying polyurethane is straightforward: clean and sand the surface, then brush or roll on the product in thin, even coats. Let it dry between layers, and apply at least two coats for full coverage. Oil-based polyurethane tends to be more durable than water-based, although it takes longer to dry and has a stronger smell.

If you’re sealing furniture, underlayment, or decorative panels that aren’t constantly wet, polyurethane offers a balance of protection and appearance.

Method 3: Apply Epoxy Resin for Heavy Exposure?

If your plywood will face regular or direct contact with water—such as on boats, patios, or outdoor kitchens—then epoxy resin is your most reliable option. Epoxy forms a thick, impermeable barrier that not only waterproofs the plywood but also reinforces it against wear and UV rays.

To apply epoxy, you’ll need to mix resin and hardener together and work quickly, as it sets fast. The plywood should be sanded smooth beforehand, and applying multiple coats will strengthen the seal. Once cured, epoxy has a glossy, rock-solid finish that resists both water and physical damage.

Bob Vila’s expert guide explains how epoxy works and why it’s perfect for outdoor use.

Method 4: Use Sealants for Light Outdoor Protection?

If you’re building garden furniture, tool sheds, or fences, and need a faster solution, a water-repellent wood sealant is a solid choice. These products are available in both spray and brush-on formats and are designed to soak into the wood surface, creating a breathable moisture barrier.

Unlike epoxy or polyurethane, sealants don’t form a hard coating on top of the wood. Instead, they allow the plywood to expand and contract with temperature changes, which helps prevent cracking. While they need to be reapplied periodically, sealants are easy to use and budget-friendly for seasonal projects.

Sealants are especially useful if your plywood is semi-exposed—like under eaves or in garden structures that only get occasional rain.

Method 5: Choose Oil-Based Stains for Beauty and Resistance?

For projects where both appearance and durability matter—like interior furniture, cabinetry, or wall paneling—oil-based stains or varnishes offer a stylish solution. These finishes enhance the natural grain of the plywood while adding moderate water resistance.

The oil penetrates the wood and forms a subtle protective layer, which helps repel moisture and dirt. While it’s not as waterproof as epoxy or polyurethane, it’s enough to protect plywood in controlled indoor settings. The final look is warm, natural, and easy to maintain with occasional reapplication.

Conclusion

Waterproofing plywood is not just an optional upgrade—it’s a vital step in protecting your project from the effects of moisture. Whether you’re working indoors or outdoors, there’s a waterproofing method that fits your needs. Starting with marine-grade plywood simplifies the process for outdoor use, while polyurethane and epoxy offer strong protection for different levels of exposure. Sealants and oil-based finishes add flexibility and aesthetics for lighter or indoor applications.

By choosing the right technique and applying it correctly, you can keep your plywood strong, stable, and good-looking for years to come. Don’t wait for water damage to show up—seal it before it soaks in.