When choosing between MDF and plywood, durability is a key concern. The question often centers around which material offers better strength, lifespan, and resistance to wear.

Plywood lasts longer than MDF in most structural and load-bearing applications due to its layered grain structure, water resistance, and superior screw-holding ability.

While MDF is suitable for indoor furniture and decorative use, its density and vulnerability to moisture make it less durable than plywood over time, especially in high-stress or humid environments. Plywood is preferred for long-term use where strength and stability matter.

What are the structural differences between MDF and plywood?

The internal makeup of each panel defines its durability and performance.

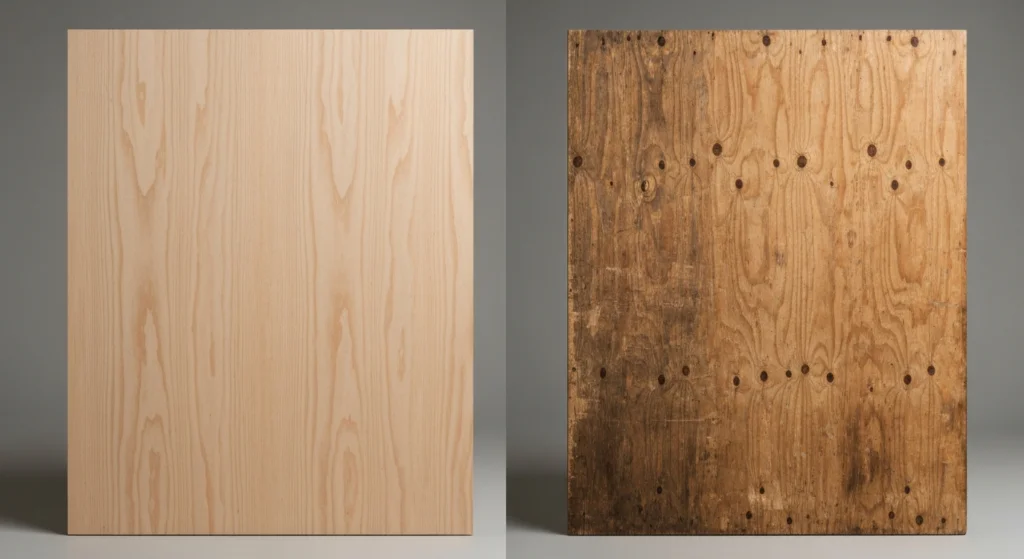

Plywood is made of cross-laminated wood veneers, while MDF consists of wood fibers bonded with resin. This makes plywood stronger and more stable than MDF.

Core structure comparison

Plywood’s layered grain direction enhances its ability to withstand bending and shear stress. Each layer adds directional strength. MDF, being uniform and fiber-based, lacks this structure, making it more prone to sagging under load.

Mechanical properties

Plywood performs better under tensile and compressive stress. MDF has a smoother surface for painting but does not hold screws as well and may split under heavy loads or over time.

How do MDF and plywood perform in moisture?

Moisture exposure significantly impacts material longevity, especially in kitchens, bathrooms, or exterior use.

Plywood resists moisture better than MDF, which tends to swell and degrade when exposed to water unless specifically treated.

Water absorption and swelling

Standard MDF absorbs water quickly and expands, losing its structural shape. Plywood may warp if unsealed but retains core strength. Exterior-grade or marine plywood includes waterproof adhesives and treated veneers for moisture-rich settings.

Mold and rot resistance

MDF, once damaged by moisture, provides a breeding ground for mold. Plywood with preservative treatment and sealed edges is better protected, especially in ventilated or outdoor applications.

Which material lasts longer under load?

Weight-bearing performance is critical for flooring, shelving, and cabinetry.

Plywood holds more weight over time without sagging, making it the better choice for structural applications.

Deflection and creep over time

MDF exhibits creep under prolonged stress, especially in unsupported spans. Plywood resists this due to its multi-directional grain. This is crucial in applications such as subfloors or furniture framing.

Fastening strength

Screws stay in place longer in plywood. In MDF, repeated fastening can cause blowouts or fiber crumbling, reducing service life in frequently assembled products.

How do factories enhance durability for each?

Material improvement depends on process control and raw material quality.

Durability increases when plywood and MDF are manufactured with strict resin control, pressing calibration, and moisture balancing systems.

Plywood manufacturing

In premium factories, plywood is pressed under controlled temperature and pressure, using high-quality phenolic resins. Each core layer is dried to the correct moisture content to avoid internal stress.

MDF enhancements

Moisture-resistant MDF is made using special waxes and resins, increasing resistance to humidity. High-density fiberboard (HDF) is a stronger variant used in flooring and high-wear products.

What are the best use cases for each material?

Selecting the right board for the right use extends its service life and ensures performance.

Plywood is best for structural and high-strength applications; MDF is suitable for painted interiors and low-impact furniture.

Ideal environments

Use plywood in places exposed to moisture, weight, or physical wear—like bathrooms, kitchens, or outdoor structures. MDF works well in dry interiors such as bookshelves, wall panels, or door skins.

Lifespan expectations

Plywood panels, especially exterior or marine-grade, can last for decades. MDF may begin to degrade in under 10 years if exposed to moisture or poor ventilation.

Conclusion

Plywood generally outlasts MDF due to its structural strength, resistance to moisture, and load-bearing capacity. Though MDF offers smoother surfaces for interior aesthetics, its lifespan is limited by environmental sensitivity. For long-term use, particularly in demanding conditions, plywood remains the superior choice.