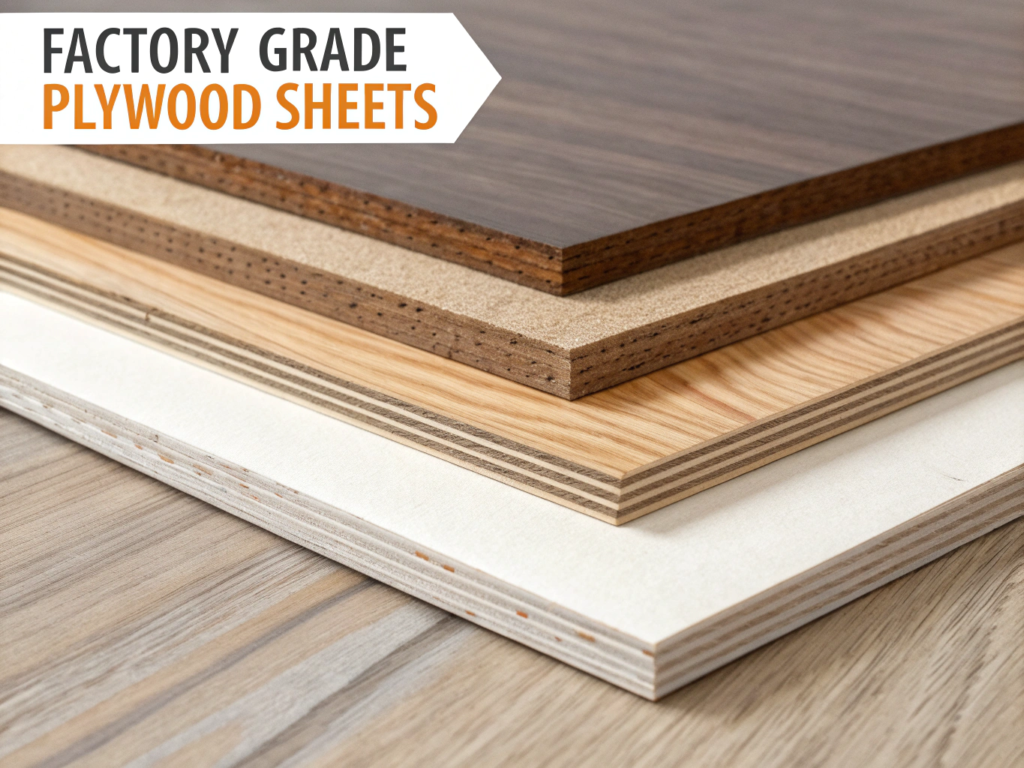

Plywood is widely used in construction and furniture, but concerns about its longevity often lead to questions about whether it can degrade or become unusable over time.

Plywood can go bad when exposed to excess moisture, UV radiation, poor handling, or inferior manufacturing. Signs include warping, delamination, mold growth, and loss of structural strength.

Despite its engineered strength, plywood is not immune to decay. Factors such as environmental exposure, poor storage, and biological threats like fungi can significantly shorten its service life. Understanding the causes and prevention methods is critical for maintaining its structural integrity.

What causes plywood to go bad?

Plywood failures are almost always linked to environmental or mechanical stress, as well as factory-level quality issues.

Moisture infiltration, UV damage, fungal decay, and poor adhesive bonding are common causes of plywood degradation.

Moisture and humidity exposure

When plywood absorbs moisture, it can swell, warp, and eventually delaminate. Repeated wet-dry cycles stress the glue lines, especially in panels not rated for exterior use. Poor sealing or edge exposure accelerates this process.

UV and temperature extremes

Sunlight breaks down surface fibers, while extreme temperature swings create internal stresses. Surface cracks and brittleness are early signs. Over time, this leads to reduced load capacity and surface layer erosion.

How does poor manufacturing contribute to plywood failure?

The foundation of a durable plywood sheet begins with consistent materials and controlled production.

Low-quality veneers, weak adhesives, uneven pressing, and moisture imbalance during production all reduce plywood’s resistance to aging.

Glue line failure

If adhesives used during pressing do not fully bond or penetrate veneer pores, the layers separate under pressure or moisture. Delamination is often first visible at panel edges.

Uneven veneer thickness or density

Inconsistent veneers introduce weak points. Sections with thinner plies or knots create stress concentrations, which accelerate splitting and cracking.

What are the early signs of plywood degradation?

Visual and structural indicators typically appear before complete failure.

Early signs include edge swelling, surface bubbling, layer separation, color changes, musty odor, or soft spots under pressure.

Surface and edge checking

Cracks, splits, and raised grain on the surface often point to long-term weather exposure or mechanical wear. Edges with flaking or softness should be sealed or replaced.

Mold and fungal presence

Black stains or white fuzz may indicate mold or mildew growth. This typically happens when plywood is left in damp, unventilated conditions. Biological activity weakens fibers and accelerates decay.

Can degraded plywood be repaired?

Minor damage can often be stabilized with sealants or reinforcements, but severe cases require replacement.

Repair depends on damage extent. Surface rot and edge swelling may be patched, but structural delamination or fungal infiltration often necessitates panel replacement.

Surface repair options

Sanding away weathered surfaces followed by application of epoxy or wood filler can restore minor defects. Repainting or sealing adds a new protective layer.

When replacement is necessary

If layers separate or mold reaches deep into the core, the panel should be replaced. Load-bearing panels with internal rot no longer meet safety standards and pose risk if reused.

How do storage and handling affect plywood condition?

Proper storage and care play a critical role in preserving plywood before and after installation.

Plywood must be stored flat, protected from moisture, and off the ground. Poor handling often leads to dents, edge chipping, or stress fractures.

Ideal storage environment

Store plywood in dry, shaded areas with good ventilation. Use pallets or racks to keep sheets elevated from concrete or wet floors. Cover with breathable tarps to prevent condensation.

Handling precautions

Use two-person lifting for large sheets to prevent cracking. Avoid dragging panels across abrasive surfaces. Always carry panels vertically to minimize bending stress and edge contact.

How do high-end factories reduce plywood failure risk?

Top manufacturers build durability into every layer using strict standards, advanced machines, and quality materials.

Well-run factories reduce plywood failure risk through calibrated equipment, certified adhesives, trained technicians, and stringent testing protocols.

Manufacturing precision

Precision veneer slicing and computerized moisture calibration ensure each ply matches the required specifications. This balance eliminates internal stress during pressing.

Post-production testing

Professional facilities perform boil tests, stress testing, and visual inspection on random samples from each batch. Only conforming products are packed for shipment. This ensures the plywood reaching end users is stable and long-lasting.

Conclusion

Plywood can go bad due to moisture, UV exposure, fungal growth, or poor production quality. Early symptoms such as warping or delamination should be addressed quickly. With high-grade materials, professional manufacturing, and proper care, plywood panels can serve reliably for years. Prevention begins with selecting panels from reputable factories, handling with care, and ensuring proper sealing and storage throughout their service life.